The aim of CNC technology is to make serial and error-free manufacturing through machines without the need for manpower. For example, parts that can be processed in an hour on a lathe and manufactured in a few pieces can be produced in hundreds of pieces in minutes, thanks to CNC technology. For this reason, CNC machines are frequently used in the manufacturing industry today.

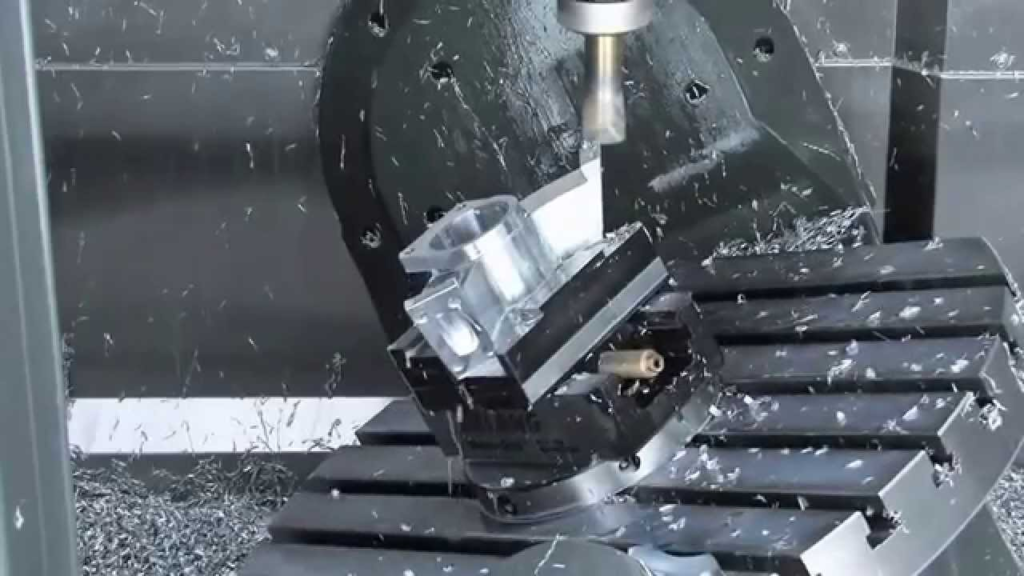

So, what is a CNC milling machine? CNC milling machine is the name given to machines that remove chips from workpieces by generally making a linear advancement movement with a pocket knife that has more than one cutting edge. This type of bench is used for purposes such as processing flat and angled surfaces, grooving, and making straight and circular divisions. For this reason, they are widely preferred in the manufacturing sector in various fields, from automotive to aviation, from defense to machinery manufacturing.

CNC milling machine parts

CNC milling machine parts can be examined under three separate headings: main parts, headings and accessories.

- Main parts: Body, console, carriage, table

- Heads: Milling machine heads

- Accessories: Mandrels, divisor and striker, rotary table, vises, clamping shoes

Details of CNC milling process

CNC milling machines are highly advanced machines with data processing and evaluation capabilities. For CNC milling, the part is connected to the machine and the reference points of the part are defined to the machine through a precision receiving tip called a probe. In this way, the machine understands the raw size of the piece to be processed and its position on the machine. In CNC milling machines, the necessary cutting tools are placed in a mechanism called a magazine.

Then, the previously prepared program to process the part is entered into the machine using methods such as control panel or memory card. It processes the part by interpreting the program entered into the machine and completely executing the tasks in the program. Here are the details of the CNC milling process and the working principle of CNC milling.

The operations performed on the CNC milling machine are named after the name of the cutting tool used or the name of the milling operation performed. Face milling, slot milling, gear cutting, etc. can be given as examples of these processes.

As we mentioned in the introduction of our article, CNC milling machines are widely used in the machinery and manufacturing sectors today. Thanks to CNC technology, machine parts can be produced flawlessly, quickly and economically in many sectors such as automotive, aerospace, defense, machinery manufacturing and mold making. CNC milling machine enables rapid and error-free manufacturing.