Today, the areas of use of CNC in industry are the part of the industry that we call machining and the area where CNC is most widely used.

When a three-axis milling machine was first used in 1952, it was perfect for solving some of the manufacturing problems of that day. These systems applied to milling machines are later used in lathes, grinding machines, etc. also applied to machine tools. Today, CNC is used in almost every field of manufacturing.

The main areas where CNC is used are;

- Machining.

- Fabrication and welding.

- Press works Inspection and control.

- Assembly.

- Transportation of materials.

CNC MACHINES:

A- CNC LATHE MACHINES:

In numerically controlled lathes, there are generally two basic axes, X and Z axis. Many profile turning operations should be possible on such machine tools. These are done with the linear interpolation and circular interpolation process features. In addition, the number of revolutions and cutter changing, determining the feed rate, etc. They have functions.

In CNC lathes with larger processing capacities, the number of axes can be 3 or more. The third axis can be the axis movement of the machine turret. The areas of use of CNC in the industry are to increase the structural resistance of the machine and to perform more precise manufacturing, especially in industrial type CNC lathes. In order to remove the emerging chips from the cutting area, some design changes have been made in the structural details.

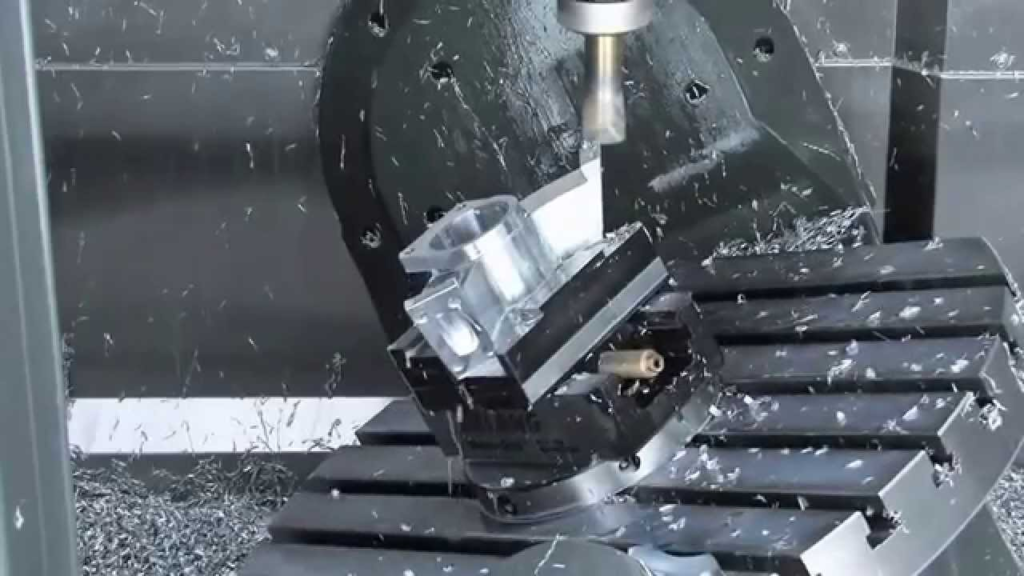

As a result, CNC Milling machines are the machines with the most processing capabilities after machining centers in terms of the diversity of operational capabilities. These types of machines have the ability to operate on at least 3, 4-5 or more axes.

All types of these machines are equipped with continuous path control. In addition, automatic cutter change (Automatic Tool Change) is another feature. In addition, Cutter compensation provides great convenience, especially in curved milling operations and mold making.

It successfully processes three-dimensional (3D) workpieces with ideal profiles and optimum properties. The cutters used are hard metal and titanium coated tips with radiused tips and high cutting speed.

B- CNC MACHINING CENTERS:

These types of CNC machines are equipped with point to point and continuous trace control (CPC). The manufacturing of workpieces with such complex and multiple operations is carried out in one assembly.

a- Horizontal machining center

b- Vertical machining center